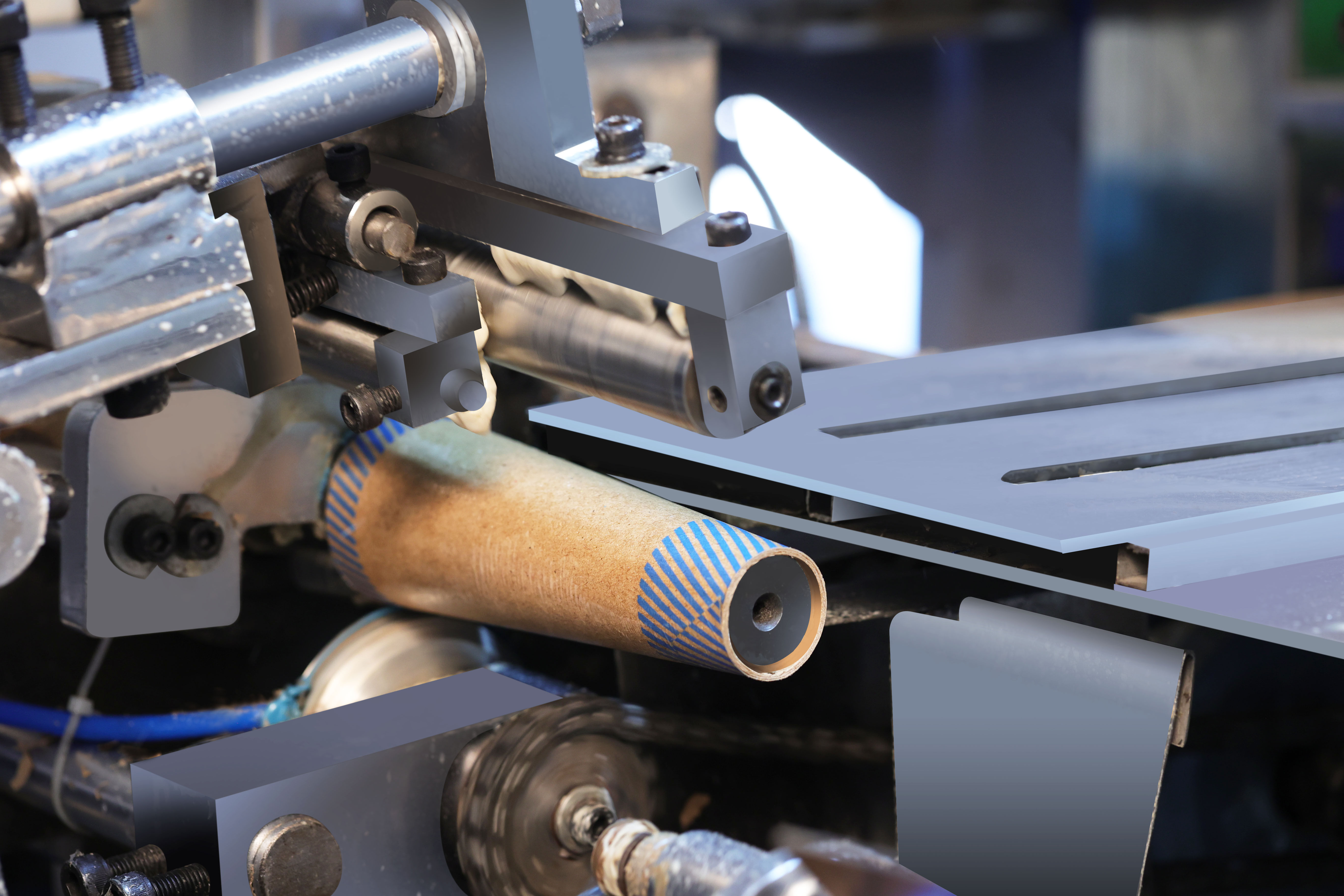

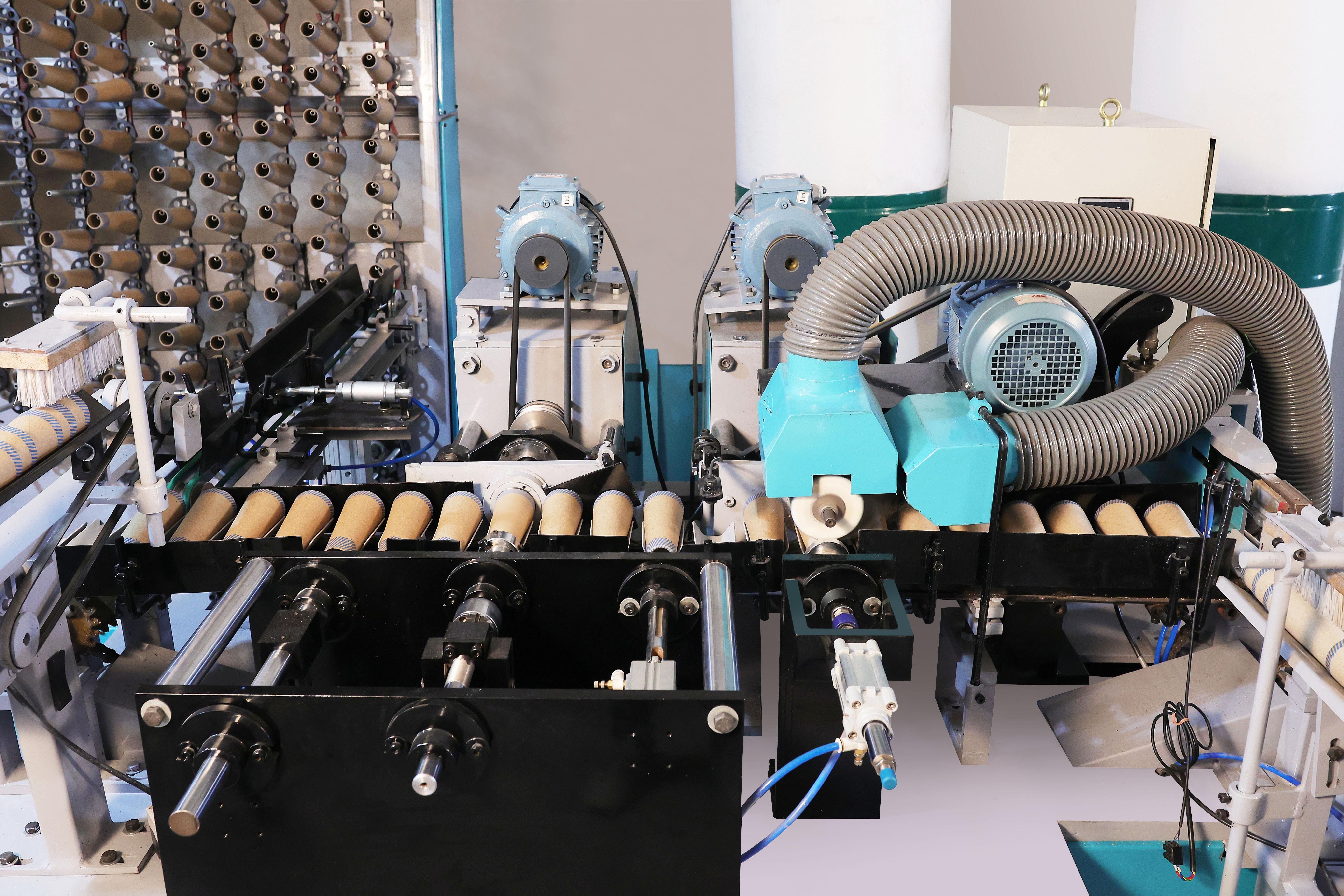

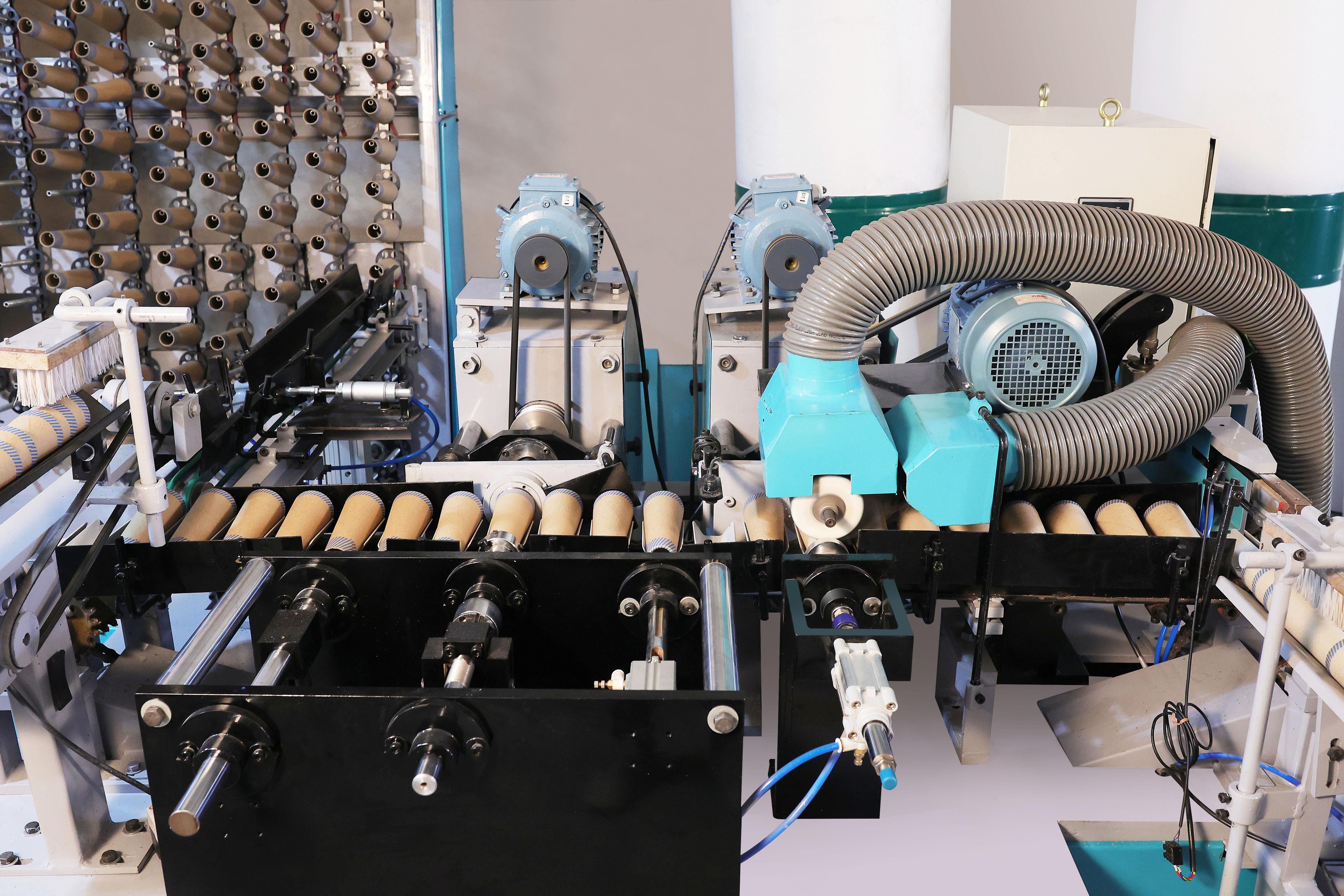

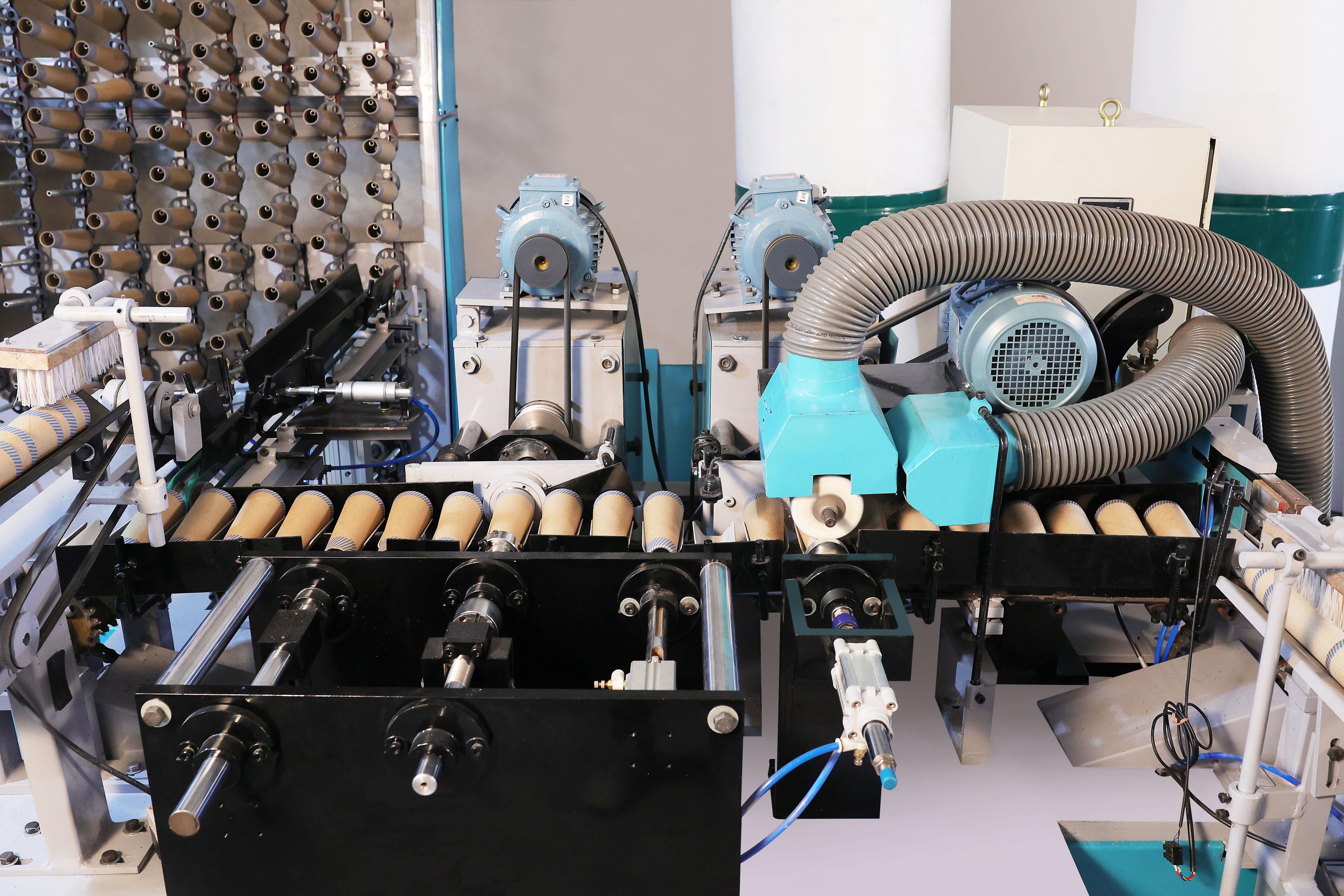

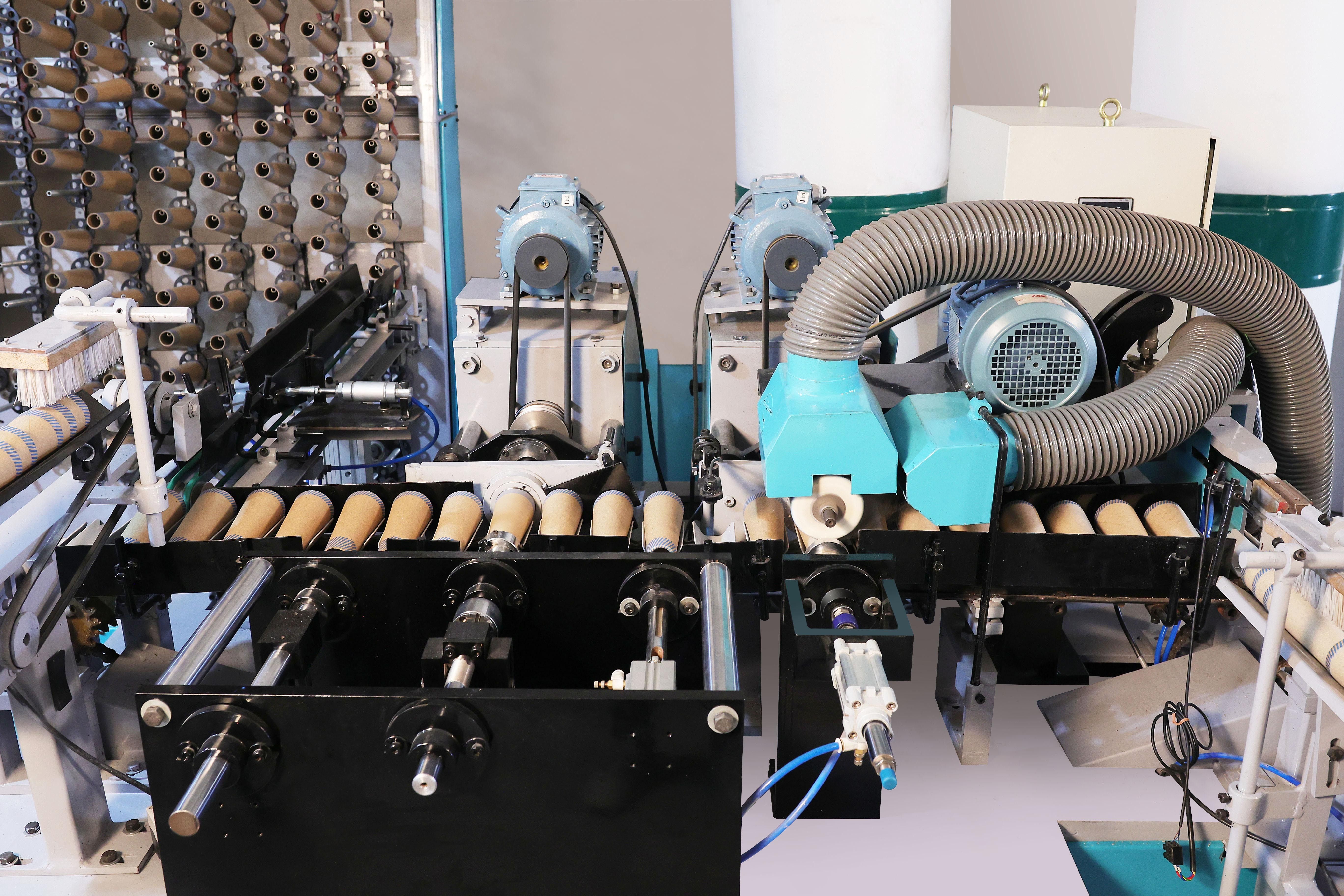

Paper Cone Making Machine

MOQ : 1 Unit

Paper Cone Making Machine Specification

- Grade

- Automatic

- Type

- Other

- Material

- Mild Steel

- Capacity

- Up to 40,000 cones per 8 hr shift

- Computerized

- No

- Control System

- Human Machine Interface

- Cutting Speed

- 50-60 cones/min

- Cutting Size

- Variable, customizable based on requirement

- Cutting Thickness

- 1-4 mm

- Voltage

- 220 - 380 Volt (v)

- Power

- 2-3 kW

- Weight (kg)

- Approx. 1500 kg

- Dimension (L*W*H)

- 3500 x 1200 x 1800 mm

- Color

- Blue & White

- Operation

- PLC Controlled

- Production Line Compatibility

- Can be integrated with existing production line

- Air Pressure Needed

- 6-8 kg/cm2

- Safety Features

- Equipped with emergency stop and safety guards

- Cone Angle

- Customized as per requirement

- Drive System

- Chain and Gear Driven

- Glue Application

- Automatic

- Paper Feeding

- Automatic

- Application

- Textile Yarn Packaging, Thread Winding

- Noise Level

- <75 dB

Paper Cone Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 45 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Paper Cone Making Machine

Product Specifications

| Grade | Automatic |

| Type | Other |

| Material | Stainless Steel, Mild Steel |

| Capacity | 48-55 Pcs/min |

| Computerized | No |

| Control System | PLC Control |

| Voltage | 390-430 Volt (v) |

| Power | 50 Horsepower (HP) |

| Weight (kg) | 9 Tonne |

| Dimension (L*W*H) | 40x20x10 Foot (ft) |

| Color | machine gray and tempo blue |

| Warranty | 1 Years |

| Supply Ability | 3 Per Month |

| Delivery Time | 45 Days |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

Product Overview

Key Features

This is fully automatic paper cone making machine with online dryer and finishing machine

Company Details

We are leading manufacturer and supplier of machines in India. Since 2007, we are dealing in this field and we have well capable and experienced team with us. We are known for providing advanced technology equipped machines which are user-friendly and giving full customer satisfaction by providing great after sell services.

High Production Capacity and Customization

Engineered for intensive industrial use, the Paper Cone Making Machine delivers a capacity of up to 40,000 cones within an 8-hour shift. The machines cone angle, size, and thickness are easily tailored to unique requirements, ensuring a precise fit for varied end uses in textile yarn packaging and thread winding. Its automatic paper feeding and glue application further streamline workflows, reducing labor demands.

Advanced Automation and Safety

Featuring PLC controls and a Human Machine Interface, operators benefit from efficient management and clear access to operational parameters. Enhanced safety mechanisms, including emergency stops and safety guards, help protect personnel during use. The automatic functions, such as paper feeding and glue application, minimize manual errors and lower operational risk.

Integration and Versatile Applications

This chain and gear-driven system is designed for seamless integration into your current production line. Whether you are an exporter, manufacturer, or supplier, this machines flexibility, reliability, and robust design make it suitable for a variety of manufacturing environments and production scales across India and beyond.

FAQs of Paper Cone Making Machine:

Q: How does the Paper Cone Making Machine ensure precise and customizable cone production?

A: The machine features adjustable settings for cone angle, size, and cutting thickness, allowing users to customize cones as per their requirements. Its PLC-controlled operation and automatic paper feeding ensure uniformity and precision in every batch.Q: What safety features are included in the machine to protect operators?

A: The Paper Cone Making Machine is equipped with emergency stop buttons and protective safety guards, which help prevent accidents and ensure a safe working environment during operation.Q: When should the air pressure be checked and maintained?

A: It is recommended to regularly monitor the air pressure, which should be kept between 6-8 kg/cm2 for optimal performance. Regular checks ensure smooth pneumatic operations and help prevent unplanned downtime.Q: Where can this machine be integrated within an existing production line?

A: The machine is designed for seamless integration with existing textile yarn packaging or thread winding production lines, making it suitable for use in a variety of industrial setups across manufacturing facilities.Q: What is the process for operating this automated paper cone machine?

A: Operators use the Human Machine Interface to configure settings such as cone dimensions and speed. The automated system handles paper feeding, glue application, and cutting. After initial setup, minimal manual supervision is required, as the PLC manages the entire process.Q: How does this machine benefit textile manufacturers and exporters?

A: With fast production rates, customizable output, and reduced manual labor through automation, textile manufacturers and exporters enjoy enhanced productivity, consistent quality, and adaptable operation to meet different market demands.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paper Cone Making Machine Category

Fully Automatic Paper Cone Making Machine

Minimum Order Quantity : 1 Piece

Type : Other

Dimension (L*W*H) : 40x20x10 Foot (ft)

Control System : PLC Control

Weight (kg) : 9 Tonne

Power : 50 Horsepower (HP)

|

TIRTH CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry